The Challenge: Having 8 teams of 2 people, each team given a task, complete an assembly line that successfully marks each side of a dice and arranges them for shipment in groups of 6. 6 teams mark one of the 6 sides of the dice, and teams 1 and 8 prepare for marking and shipment, respectively.

Our Solution:

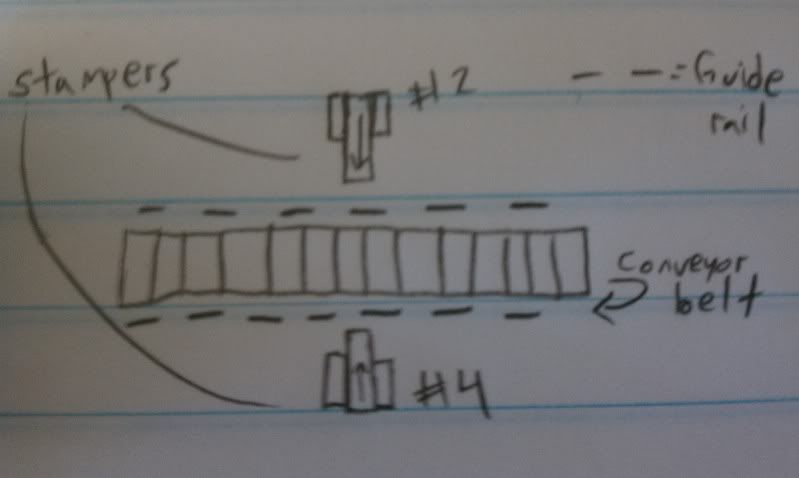

Design Overview: Being team 3 (meaning we would mark side 2), we decided to collaborate with team 5 who would mark the opposite side 4. Since the they were on opposite ends, from the start it was decided that there would be some sort of marker that would stamp the dice from both sides simultaneously, making what would have been 2 separate projects into one.

# of Achievements Earned: 17

Achievement Breakdown:

Class:

- Implementation (Project was finished according to criteria and constraints)

- Stewardship (Class cleaned up for project entirely)

Team:

- Proof is in the pudding (Project shown connected to other parts of the project above)

- Round and Round We Go (Guide rails put in after cube kept falling off of conveyor belt)

- Round and Round We Go... Again (Conveyor belt drooping too much, put in a frame under it so that it wouldn't be too tight but would be level)

- No Soliciting (Listed below)

Sustain - simultaneous two side stamping.

Change - Should have used pneumatics.

Question - How is your stamper triggered?

Idea - put a frame under conveyor belt to keep it level.

- Lab Rat (Collected time it took for dice to get through, got average of 6.75s)

- Show Me (Shown below)

- Leave No Trace (all our parts where placed in a temporary bin and then sorted)

Individual:

- Share It (Listed below)

Sustain - pneumatics for the teams that used it, ended up being much better off.

Change - uniform height for all the separate projects, height differences were a problem.

Question - How can you make your conveyor belt not be as inconsistent? to team 4.

Idea - For all teams, maybe just use one conveyor belt with uniform speed and build around the conveyor belt.

- Keep the Customer in Mind (Up to you Mr. Olson)

- Nice One! (Cody was helpful with making our conveyor belt not jump around as much)

- Helping Hand (I helped Niki and Morgan with their initial program for their project)

- Meta Gamer (The more team achievements you have, the greater of a "safety net" you have. If you were someone who had very little team and individual achievements, the class achievements could save you.)

- And The Winners Are (Listed Below)

Initiative - Cody took the initiative of fixing up the last part of the project that he believed wasn't working as it should

Sportsmanship - Jackson didn't take it entirely badly when another team remade his part of the project.

Collaboration - Marco was leading the effort to get the different parts of the project to interact correctly

Humor - Nick Robles by keeping a productive mood.

Teamwork - Andoni, agreed with me to merge both our parts of the project.

No comments:

Post a Comment